A new robot searches for materials for solar cells 14 times faster

Aram Amassian

Earlier this year, double-layer solar cells broke records with an efficiency of 33%. The cells are made of a mixture of silicon and a material called perovskite. However, these tandem solar cells are still far from the theoretical limit of about 45% efficiency, and they degrade quickly under exposure to sunlight, which limits their usefulness.

The process of optimizing tandem solar cells involves finding the perfect materials to layer on top of each other, each capturing some of the sunlight that the other misses. One possible material for this is perovskite, which is defined by its characteristic crystal structure in a cubic rhombic shape. This structure can be adopted by many chemicals in a variety of proportions. To make a good candidate for tandem solar cells, the mixture of chemicals must have the right bandgap—the property responsible for absorbing the right part of the sun’s spectrum—and be stable at room temperature, and, even harder, not degrade under illumination.

The number of potential perovskite materials is very large, and predicting what properties a given chemical composition will have is very difficult. Trying all the possibilities in a lab is very expensive and time consuming. To speed up the search for the perfect perovskite, researchers at North Carolina State University decided to turn to robotics.

Chemical search automation

“We are dealing with physical variables every time we improve this technology,” said Aram Amassian, a professor at NCSU and the principal investigator on the project. “So we need to be able to create new materials and evaluate these materials. And anyone who looks at these materials has to do very repetitive and intensive work.

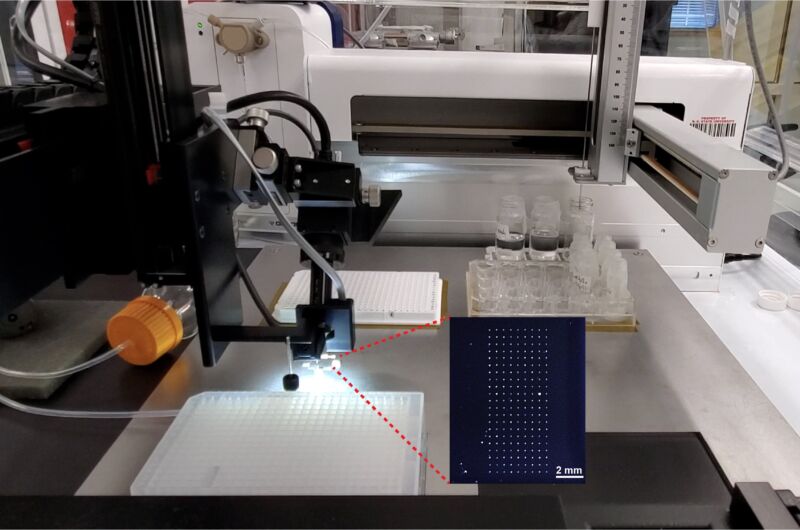

To cut back on that work, Amassian’s team built a robot, which they called RoboMapper. RoboMapper has two main parts that work together. The first is the ink preparation robot. Given a set of basic chemicals, this robot collects them in different proportions and synthesizes them into hundreds of inks that potentially make up perovskites. The second is a printing robot, which applies these inks in a grid onto a single substrate.

Being able to put hundreds of tiny samples onto a single slide, a task impossible with human ingenuity, enables researchers to test all of these samples simultaneously with different diagnostic tools. The researchers say this speeds up the material synthesis and characterization process by a factor of 14 compared to manual exploration and by a factor of nine compared to other automated methods.

To demonstrate RoboMapper’s capabilities, the researchers tested a select group of potential perovskite mixtures. They used a RoboMapper to mix three basic ingredients in hundreds of different ratios and print all the samples on a single slide. They then tested these samples to determine their structure, band gap, and stability under light exposure. From these accelerated tests, they built quantitative models of how these critical properties might vary with the changing composition. “We are able to build predictive models and look at the areas between data points,” Amassian said. “Sometimes the best combinations may be in unexpected areas of the chemical composition space.”

Using a RoboMapper workflow, the research team succeeded in identifying an “ideal” perovskite mixture that showed the properties required for use in tandem solar cells. This sample had the correct band gap and also deteriorated slowly under light exposure compared to the alternatives.

Work in progress

This discovery represents an initial step in the journey towards developing tandem solar cell technology. Amassien’s team only tested perovskite itself, not combining it with silicon (or any other substrate) to create tandem cells. But researchers are using their accelerating tool to test other potential mixtures and quickly find promising new candidates.

Using RoboMapper not only saves researchers time, but also reduces the energy cost of testing new materials. In fact, with this technique, testing a single material might cost less energy than it would take to simulate its properties with computers. This will allow researchers to generate more real-world data for direct use or smooth machine learning techniques. “To train machine learning and AI models, for example, we need more data,” Amassian said. “We need higher quality data. And we need efficient high-dimensional space exploration.

This approach is not limited to perovskite or solar cell applications, but is already being used to enable data-driven semiconductor research. “When we designed RoboMapper, we designed it to be very flexible, modular, and extensible,” Amassian said. Any searches for materials that can be made with inking technology can be accelerated using this technology, including printed electronics, because RoboMapper is primarily a robot that drafts and prints inky materials on demand.

Theme2023. Digital ID: 10.1016/j.matt.2023.06.040

Dina Genkina is a freelance science writer and podcaster based in Brooklyn and science communicator at the Joint Quantum Institute. She is interested in quantum physics, artificial intelligence, climate technology, and other cool things.

Source link