How do aerosols affect the maintenance of aircraft engines?

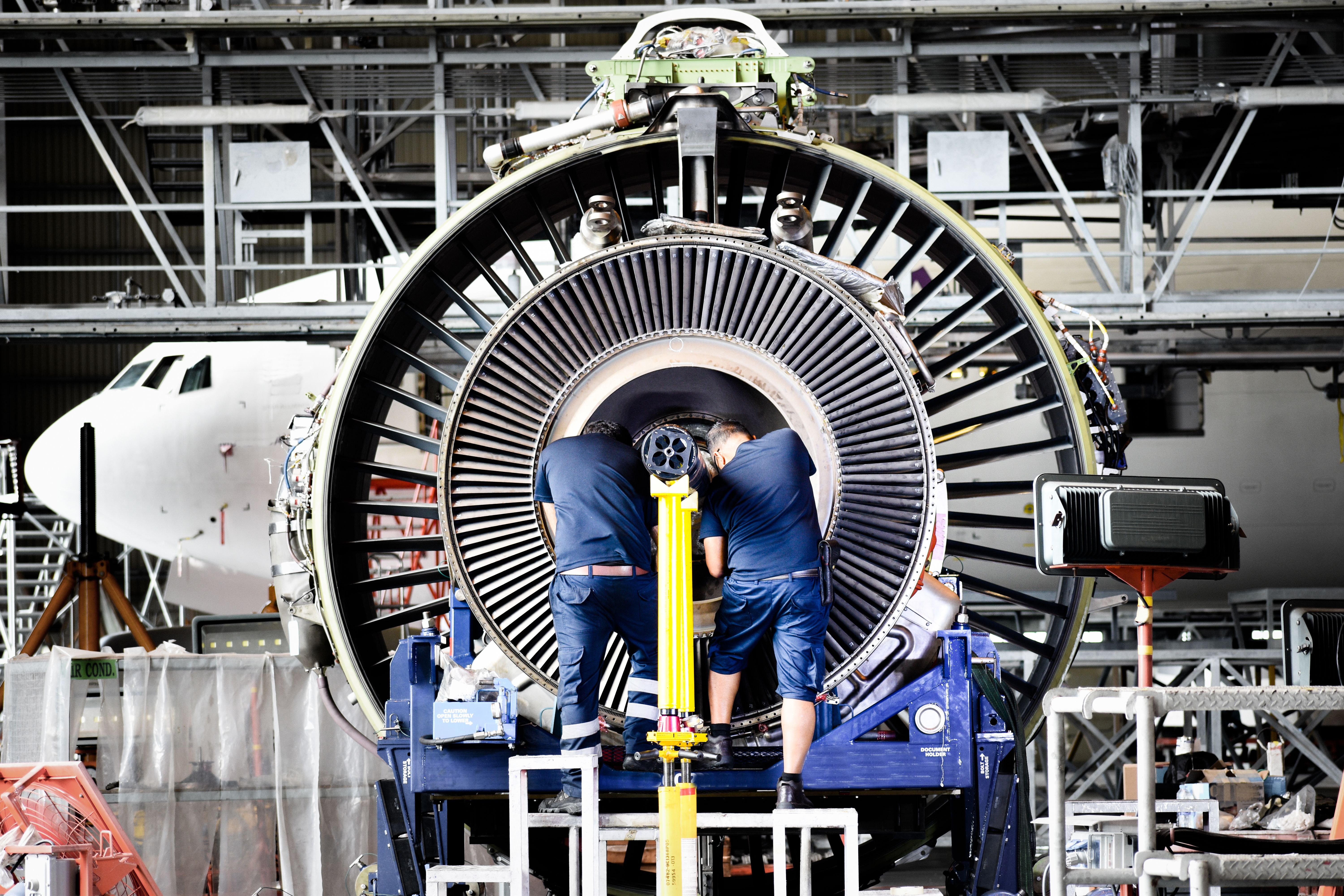

Jet engines are complex machines that require excellent service and regular maintenance. The engine may be taken off the wing due to an operational failure or an accident during flight. However, routine maintenance checks are often the main reason for a maintenance visit. An incoming inspection generally reveals the extent of wear and damage to the engine during operation.

Jet engines are exposed to harsh environments during operation. From rain and hail to other environmental debris, engines are designed to take it all in and keep going. However, some environmental aerosols damage the engine more than others.

Such aerosols include the salty air of coastal airports, mineral dust from desert sands, sulfate air pollutants, and black carbon from wildfire smoke or volcanic ash. This aerosol can damage moving parts inside engines through corrosion, wear, or blockage of important valves and nozzles.

Determination of corrosion and damage

There are various techniques used to predict and quantify engine wear due to aerosol exposure. Meteorologists periodically collect and analyze atmospheric data to find out the concentration of aerosols in a particular region or pair of cities. The analysis also shows dispersal patterns which are then linked to aircraft movements in the area.

Computer models of aerosol concentration and dispersion also highlight the potential impact on engine parts exposed to the environment. From environmental data and flight history, exposure to environmental aerosols is estimated, and measures are taken to increase engine inspection and maintenance.

The effect of environmental factors on engine maintenance

Commercial jet engines are sensitive to potential damage from the environments in which they fly. Severe environmental factors affect the life cycle of an engine. For example, the life cycle of CFM International CFM56 engines operating in desert areas in the Middle East is much shorter than those operating in cold environments and at sea level.

The engine will have significant exposure to sand but relatively light exposure to sea salt, sulfates, and carbon black. Engines with a profile like this require frequent inspections for any abrasive damage. As such, the period between routine inspections is shorter if the chances of severe environmental damage are higher.

Photo: Santi Lumopol/Shutterstock

Preventive maintenance practices seek to account for exposure to such aerosols, and alter the time between overhaul (TBO) of engine parts as prescribed by international regulations. Almost all critical and non-critical systems undergo regular inspection and maintenance to prevent damage from aerosol exposure.

Environmental correction factors are calculated based on the average aerosol exposure for specific areas for preventive maintenance scheduling. It is worth noting that accidents or short periods of unusually high exposure can lead to extremely accelerated deterioration of engine components.

Therefore, preventive maintenance based on specific intervals may not be very effective in such cases. Aircraft operators use conditional maintenance where routine, targeted inspections indicate the extent of wear or damage to engine components. Maintenance scheduling on an aircraft-by-aircraft basis helps avoid mechanical failures and costs resulting from schedule disruption.

What are your thoughts on the effects of environmental aerosols on aircraft and engines? Tell us in the comments section.

Source link